55. Giga Texas

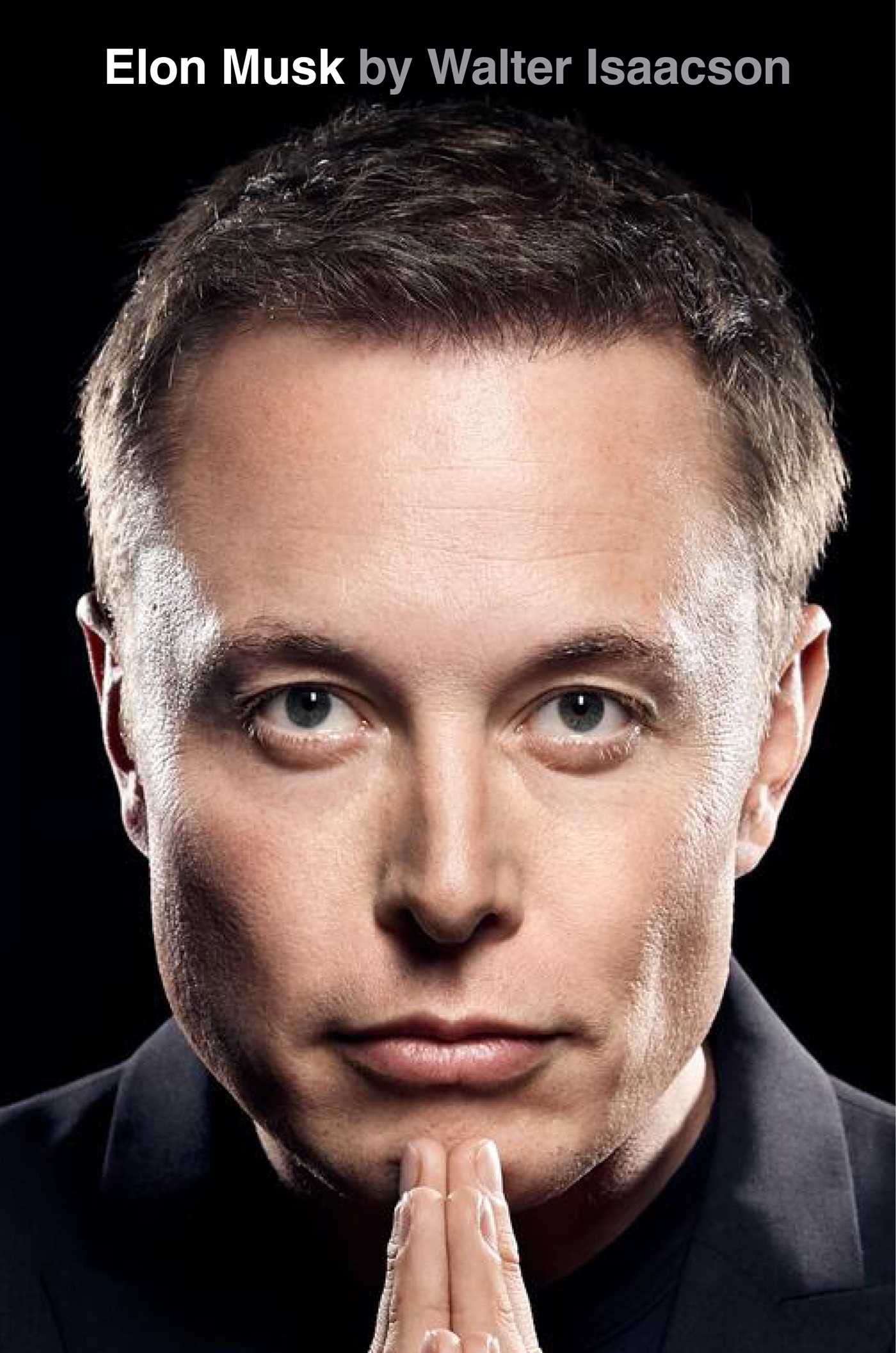

byGiga Texas became a key milestone in Tesla’s expansion strategy in early 2020 when Elon Musk and his executive team, including Omead Afshar, explored potential locations for the next Gigafactory. As Tesla’s Fremont plant neared full capacity, the need for a larger, more efficient manufacturing hub became increasingly evident. Various U.S. cities were considered, but Musk sought a location that would align with his long-term vision for innovation, cost-effectiveness, and regulatory ease. California’s stringent regulations and high operating costs pushed Tesla to look elsewhere, ultimately setting the stage for a move to a more business-friendly state.

Austin, Texas, quickly emerged as the top choice due to its favorable tax policies, abundance of skilled labor, and established tech ecosystem. Unlike other corporations that conducted prolonged bidding wars for new headquarters, Musk favored an instinctive, rapid decision-making process. Texas’ open embrace of business development, coupled with the state’s strong infrastructure, made it an attractive location for large-scale manufacturing. The quick acquisition of land near the Colorado River, supported by state and local incentives, ensured that Tesla could break ground almost immediately, setting in motion one of the company’s most ambitious projects.

Tesla’s expansion into Texas was not just about building a factory but about redefining the company’s approach to high-volume production. Giga Texas was designed as a fully integrated facility capable of handling everything from battery cell production to vehicle assembly under one roof. By mid-2021, the construction process moved at an unprecedented pace, with Tesla leveraging modular building techniques to accelerate progress. The facility’s footprint soon rivaled the size of some of the largest manufacturing plants in the world, reinforcing Musk’s push for vertical integration and rapid scalability.

Musk maintained a hands-on role throughout the construction phase, focusing on optimizing design efficiency and streamlining production processes. His attention to detail extended to elements like maximizing natural lighting, implementing cutting-edge cooling systems, and refining automation processes to enhance manufacturing speed. The factory’s architecture was tailored to support Tesla’s evolving automation strategies, with robotics and AI playing a significant role in assembly-line improvements. This approach reduced reliance on manual labor while increasing production output, aligning with Musk’s goal of continuously refining Tesla’s manufacturing capabilities.

One of the most revolutionary advancements at Giga Texas was the introduction of the Gigapress, a state-of-the-art high-pressure die-casting machine capable of producing entire vehicle underbodies in a single piece. Inspired by the simplicity of toy car manufacturing, Musk envisioned a method that would drastically reduce part complexity and assembly time. Partnering with Italian firm Idra Presse, Tesla acquired the largest casting machines ever built, which became instrumental in the production of the Model Y and the highly anticipated Cybertruck. This innovation streamlined production, enhanced structural integrity, and lowered costs, marking a major shift in how vehicles were manufactured.

Beyond its technical breakthroughs, Giga Texas represented Tesla’s broader vision of decentralizing its manufacturing footprint and establishing a presence in regions that supported rapid growth. The factory was strategically positioned to serve North American markets while also paving the way for further global expansion. Musk’s emphasis on operational efficiency meant that Tesla could produce vehicles at a scale previously unattainable, reinforcing its leadership in the electric vehicle industry. The facility was also designed to accommodate future production lines for new vehicle models, ensuring Tesla’s long-term adaptability.

Musk’s approach to Giga Texas reflected his broader philosophy of relentless innovation and risk-taking. His ability to challenge industry norms and push for faster, more cost-effective production methods set Tesla apart from traditional automakers. The speed and efficiency with which Giga Texas was constructed highlighted Musk’s focus on execution, proving that large-scale manufacturing projects could be completed with agility and precision. As Tesla moved forward with its plans, Giga Texas stood as a testament to Musk’s vision, positioning the company for its next phase of exponential growth in the global automotive market.